|

Quantity

|

Out of stock

|

||

|

|

|||

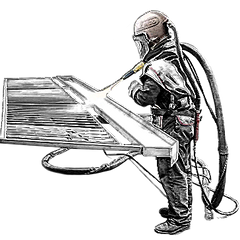

Sandblast cleaning of metal in Poltava

Sandblasting (or sandblasting) is a method of complex cleaning of various surfaces from dirt, corrosion, carbon deposits, old varnish and paint coatings, etc. The high performance and competitive price of sandblasting have made it one of the most sought-after technologies of its kind.

The most commonly used sandblasting metal, but you can work with other surfaces:

glass (sandblasting of mirrors);

concrete and brick;

tree and stone.

Such processing not only allows you to eliminate the most complex contamination and some surface defects. It makes it possible to create an accent, emphasize the decorative properties of the product. For example, highlight and make the relief more expressive, emphasize the structure and texture of the surface.

Sandblasting principles

When sandblasting a surface, compressed air, together with abrasive particles, is accelerated and fired from the gun under high pressure. To do this, a productive compressor is used, which creates the desired level of pressure. The abrasive substance with great force acts on the surface, removing even the most dense dirt or old coatings.

Modern equipment allows you to adjust the force of compressed air with high accuracy. This means that it is better to work with different surfaces. Quite sensitive too. The equipment itself is not complicated in operation, but you need to know how to work with certain materials, what degree of exposure is acceptable and whether this is enough to prepare the product for further processing. Therefore, this work should still be entrusted to the master.

Sandblasting requirements for aluminum and other metals

The standards for preparing metal surfaces for further painting and applying metallized coatings are prescribed in the relevant document - GOST 9.402-80. It states that there are 4 levels of sandblasting:

Rust and scale are invisible even at 6x magnification.

Visually, without additional equipment, no rust, scale, burns, dirt, etc. were detected.

There are visible dirt, scale, traces of corrosion, but together they occupy no more than 5% of the entire surface.

The product is cleaned only from rust and scale.

Of course, the first level is optimal. It is achieved only with the use of modern equipment, its precise settings and the professionalism of the operator who works with this equipment.

If quality is important to you, you can order sandblasting in Poltava and the Poltava region from Gruar. We have our own sets of professional equipment, a well-organized staff and careful quality control at all stages of processing.

We recommend that you first get a consultation, discuss the details of working with metal, the type and design features of the processed products. This will allow you to more accurately form the price and make an estimate for the work. And most importantly - to announce the deadlines for readiness.

You can consult or immediately order a sandblasting service in Poltava by phone number 095 005-00-25.